Why Stainless Steel Metal Strips Are Essential for Modern Manufacturing

In today’s fast-paced world, stainless steel metal strips play a pivotal role across various industries, from automotive to aerospace and electronics. These versatile materials have become the backbone of numerous production processes, offering durability, corrosion resistance, and flexibility. But what makes stainless steel metal strips so important? And why should manufacturers like Jianglin focus on producing top-quality metal strips for businesses worldwide?

In this blog post, we will dive into the benefits, applications, and key factors that make stainless steel metal strips a staple in modern manufacturing. We will also explore the advantages of working with experienced manufacturers like Jianglin, who specialize in providing high-performance metal strips for diverse industries.

What Are Stainless Steel Metal Strips?

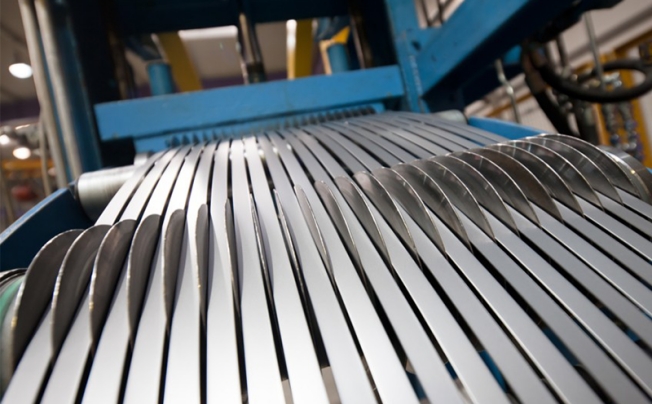

Before we get into the various applications, let’s first understand what stainless steel metal strips are. Stainless steel strips are flat pieces of stainless steel that have been carefully processed and cut into thin, long forms. These strips are usually characterized by their excellent corrosion resistance, strength, and aesthetic appeal. Stainless steel strips can be made in different grades, such as 304, 316, and 430, depending on their intended application.

Stainless steel strips can come in different thicknesses, widths, and finishes, making them adaptable for several manufacturing and engineering purposes. Whether it’s in the construction of medical devices, the automotive industry, or even household appliances, stainless steel strips have become a go-to choice for creating durable and reliable products.

The Advantages of Stainless Steel Metal Strips

1. Corrosion Resistance

One of the primary reasons manufacturers choose stainless steel is its exceptional resistance to corrosion. Stainless steel alloys contain chromium, which forms a protective layer on the surface. This layer shields the steel from environmental factors such as moisture, chemicals, and high temperatures. As a result, stainless steel metal strips maintain their appearance and performance even in harsh conditions, making them ideal for outdoor applications or industries where materials are exposed to corrosive substances.

2. Durability and Strength

Stainless steel is renowned for its impressive strength-to-weight ratio. Even in thinner strips, stainless steel retains remarkable durability and resilience. For industries like aerospace, automotive, and construction, this strength is crucial for ensuring the safety and longevity of products. Stainless steel metal strips are resistant to wear and tear, ensuring that they won’t easily degrade over time, even under heavy use.

3. Aesthetic Appeal

Stainless steel has a sleek, modern appearance that is perfect for industries where aesthetics matter. In sectors like architecture, electronics, and interior design, stainless steel metal strips offer an elegant finish that doesn’t compromise on strength. Whether it’s used in decorative elements or visible components, stainless steel’s natural shine and smooth finish add a polished, high-end look to any product.

4. Versatility in Manufacturing

Stainless steel metal strips are incredibly versatile. Manufacturers can form, cut, and weld these strips into virtually any shape or size required. Whether it’s for making small components or larger structural pieces, stainless steel strips can be processed to meet the exact specifications of a wide range of applications. Moreover, their ability to withstand extreme temperatures and pressures adds to their flexibility in various manufacturing processes.

How Stainless Steel Metal Strips are Used in Manufacturing

Stainless steel metal strips are not just used in one industry. They have found applications across numerous sectors due to their wide range of properties. Let’s take a closer look at some of the industries where stainless steel strips are commonly used.

1. Automotive Industry

The automotive industry relies heavily on stainless steel for its durability and lightweight properties. Stainless steel metal strips are used in the manufacturing of car body panels, engine parts, exhaust systems, and more. In fact, the automotive industry is one of the largest consumers of stainless steel, with metal strips playing a vital role in improving the performance and longevity of vehicles.

2. Aerospace Industry

In the aerospace sector, stainless steel metal strips are used in everything from aircraft components to space vehicles. The high strength and corrosion resistance of stainless steel make it an ideal material for building parts that need to withstand the extreme conditions of flight. Stainless steel strips are used for manufacturing structural components, fasteners, and other critical parts in the aerospace industry.

3. Medical Devices and Equipment

The medical field also benefits from the use of stainless steel metal strips. From surgical instruments to implants, stainless steel is the go-to material for medical devices due to its ability to resist bacteria, corrosion, and wear. Additionally, its biocompatibility ensures that stainless steel does not cause harm to human tissue, making it perfect for use in the healthcare industry.

4. Construction and Architecture

Stainless steel metal strips are widely used in construction, especially for architectural purposes. Whether it’s for structural reinforcement, roofing materials, or decorative elements, stainless steel offers unmatched strength and longevity. Many modern buildings and infrastructure projects use stainless steel strips for their sleek appearance and resistance to weathering, ensuring that the building lasts for decades without requiring constant maintenance.

5. Electronics Industry

The electronics industry uses stainless steel metal strips for everything from connectors to housings and other internal components. Stainless steel’s ability to resist corrosion and maintain its structural integrity makes it a popular choice for producing durable and long-lasting electronic devices. Whether it’s in smartphones, computers, or home appliances, stainless steel parts can be found in a wide range of consumer electronics.

Key Factors to Consider When Choosing Stainless Steel Metal Strips

When selecting stainless steel metal strips for a specific application, manufacturers must consider several factors to ensure the material meets the requirements of the project. These factors include:

1. Grade of Stainless Steel

Different grades of stainless steel offer varying properties, such as strength, corrosion resistance, and formability. Common grades like 304 and 316 are known for their general versatility and corrosion resistance, making them suitable for a wide range of applications. However, more specialized projects might require different grades, such as 430 for applications where magnetic properties are needed.

2. Thickness and Width

The thickness and width of the stainless steel strip play a critical role in determining its strength and suitability for a given application. Thicker strips are often used in heavy-duty applications, while thinner strips are ideal for more delicate tasks. It’s important to choose the correct size to ensure that the material performs optimally in the final product.

3. Finish

Stainless steel metal strips come in different finishes, such as polished, matte, or brushed. The choice of finish will impact the appearance of the final product and may also affect its performance. For example, a polished finish offers superior corrosion resistance but may be more prone to scratches, while a matte finish can be more durable but may not have the same aesthetic appeal.

4. Formability and Weldability

Formability refers to the ability of the metal strip to be shaped or bent without breaking, while weldability refers to its ability to be welded without compromising its structural integrity. Depending on the project requirements, it’s essential to choose stainless steel strips that are easy to form or weld, especially for complex manufacturing processes.

Why Choose Jianglin for Stainless Steel Metal Strips?

At Jianglin, we specialize in producing high-quality stainless steel metal strips that meet the rigorous demands of various industries. As a trusted manufacturer, we offer a wide range of stainless steel grades, finishes, and thicknesses to suit every project. Whether you’re in the automotive, aerospace, medical, or construction sector, we have the expertise and resources to provide tailored solutions for your needs.

Our commitment to quality ensures that our stainless steel metal strips maintain their integrity and performance throughout their lifespan. With state-of-the-art production processes and strict quality control standards, we provide our clients with reliable and durable materials that meet the highest industry standards.

Conclusion: Embrace the Power of Stainless Steel Metal Strips

Stainless steel metal strips are an essential part of modern manufacturing, offering benefits like corrosion resistance, durability, aesthetic appeal, and versatility. With applications spanning industries from automotive to aerospace, medical devices to electronics, these strips are a crucial element in the production of high-quality products. Choosing the right stainless steel metal strip for your project can make all the difference in the long-term performance and reliability of your end product.

By partnering with a trusted manufacturer like Jianglin, you can be confident in receiving stainless steel metal strips that are tailored to your specific needs. So, whether you’re building vehicles, aircraft, medical devices, or cutting-edge technology, stainless steel metal strips are the ideal solution for achieving high-quality, long-lasting results.